The focus of our Brazilian operations is direct container load shipments from Brazil to the foreign port of import. Brazil is one of the world’s most important manufacturing countries of construction pine plywood & decorative hardwood plywood. Brazil’s manufacturing output exceeds local demand, so they are dependent on export sales to support the large volumes of plywood production.

Sea Corporation Lumber first began working with Brazilian manufacturing companies back in 2006. You can trust Sea Corporation Lumber to handle your Brazilian import orders with supply of quality plywood products at competitive prices. The main product categories we supply from Brazil are below.

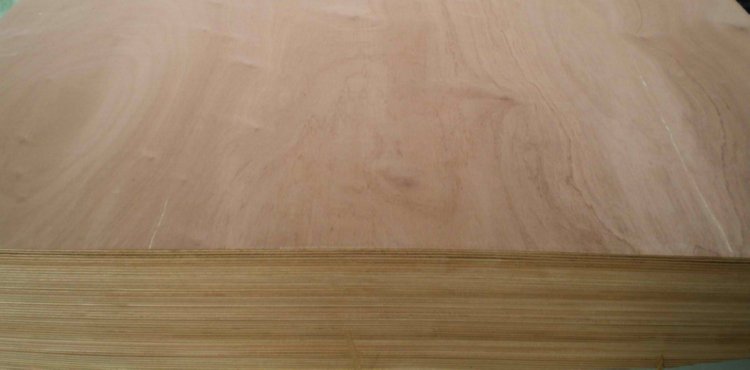

Sea Corporation Lumber ships full container loads of pine plywood from Brazil directly to our clients. The predominant species in Brazil are Pinus elliotti (similar to Slash Pine in USA) and Pinus taeda (similar to Loblolly Pine in USA). Exterior pine plywood is manufactured with phenolic based WBP glue for a strong glue line in both wet and dry conditions.

| Nominal Imperial | Actual Imperial | Actual Metric | Standard Pack Sizes |

|---|---|---|---|

| 1/4″ 4’x8′ 3/8″ 4’x8′ 1/2″ 4’x8′ 5/8″ 4’x8′ 3/4″ 4’x8′ | 1/4″ 4’x8′ 11/32″ 4’x8′ 15/32″ 4’x8′ 19/32″ 4’x8′ 23/32″ 4’x8′ | 6 mm 1.22×2.44 m 9 mm 1.22×2.44 m 12 mm 1.22×2.44 m 15 mm 1.22×2.44 m 18 mm 1.22×2.44 m | 150 pieces 100 pieces 75 pieces 60 pieces 50 pieces |

C+/C+ O&ES (Both sides with C grade veneer, plugged & touch sanded, oiled & edge sealed)

C+/C O&ES (Face with C grade veneer, plugged & touch sanded and Back with C grade veneer, oiled & edge sealed)

| Nominal Imperial | Actual Imperial | Actual Metric | Standard Pack Sizes |

|---|---|---|---|

| 1/2″ 4’x8′ 5/8″ 4’x8′ 3/4″ 4’x8′ | 15/32″ 4’x8′ 19/32″ 4’x8′ 23/32″ 4’x8′ | 12 mm 1.22×2.44 m 15 mm 1.22×2.44 m 18 mm 1.22×2.44 m | 75 pieces 60 pieces 50 pieces |

C+ (C grade veneer, plugged & touch sanded)

C (C grade veneer)

Builders Grade (Downfall from C grade production)

| Nominal Imperial | Actual Imperial | Actual Metric | Standard Pack Sizes |

|---|---|---|---|

| 3/8″ 4’x8′ 1/2″ 4’x8′ 5/8″ 4’x8′ 3/4″ 4’x8′ | 11/32″ 4’x8′ 15/32″ 4’x8′ 19/32″ 4’x8′ 23/32″ 4’x8′ | 9 mm 1.22×2.44 m 12 mm 1.22×2.44 m 15 mm 1.22×2.44 m 18 mm 1.22×2.44 m | 100 pieces 75 pieces 60 pieces 50 pieces |

Sea Corporation Lumber ships full container loads of Hardwood Plywood from Brazil directly to our clients. The predominant species in Brazil are Amescla, Virola, and Parica. All species have similar appearances to each other and are typically used interchangeably in production. Hardwood Plywood is usually manufactured with MR Interior Glue due to the cost savings, but phenolic based WBP Exterior glue can be specified as well.

| Grade Description | BB Face | CC Face | Overlay Face | Utility Face |

| Burls, Sound | Yes, smooth | Yes, smooth | Yes, smooth | Yes, smooth |

| Pin Knots | Sound, not clustered | Sound | Sound | Yes |

| Knots – Number/Arrangement/Size | 4 per 4′ x 8′ panel, not clustered | 6 per 4′ x 8′ panel, not clustered | not clustered | Yes |

| Sound, Live | 3/4″ max dia | 1″ max dia | 2″ max dia | Yes |

| Soft, Dead | No | well puttied & color matched | well puttied & color matched | Puttied |

| Knotholes | 3/8″ max dia | 1/2″ max dia, well puttied & color matched | 1″ max dia, well puttied & color matched | 1″ max dia, puttied |

| Color Variation | Yes | Yes | Yes | Yes |

| Stain/Mineral Streaks | No | Blending | Yes | Yes |

| Dry Pitch & bark pockets | well puttied & color matched | well puttied & color matched | well puttied & color matched | puttied |

| Wormholes, pinholes & worm tracks | 5 per 4′ x 8′ panel, 1/32″ max dia, well puttied & color matched | 32 per 4′ x 8′ panel, 5/8″ max dia, well puttied & color filled | Well puttied | Puttied |

| Vine Marks | Blending, smooth, level | Blending, smooth, level | Sanded, smooth, level | Sanded, smooth |

| Cross Breaks | No | Hairline, 2″ max length | Hairline, 4″ max length | Hairline |

| Doze | No | Firm, slight, well puttied, blending | Firm, slight, well puttied, blending | Firm, puttied |

| Joints | 1 max, tight, parallel to edge, color blending at joint | 1 max, tight, parallel to edge, color blending at joint | 1 max, tight, parallel to edge, color blending at joint | 1 |

| Splits-Open | No | Hairline, 6″ max on panel ends only | Hairline, 12″ max on panel ends only | Hairline |

| Splits, Filled or Puttied | Two, 1/16″ x 10″ or 1/8″ x 8″ at each end, color matched | Three, 1/16″ x 24″ or 1/8″ x 14″ at each end, color matched | Three at each end, color matched | Yes |

| Fill or putty smears | Color matched | Color matched | Color matched | Yes, smooth |

| Rough cut/ ruptured grain | No | Occasional, sanded, smooth | Sanded, smooth | Yes |

| Shims | 1/4″ x 6″ at ends of panel, repaired with veneer, color and grain matching | 3/4″ x 6″ at ends of panel, repaired with veneer, color and grain matching | Ends of panel, repaired with veneer, color and grain matching | Yes |

| Knife marks | No | No | 1/32″ max, smooth | Sanded, smooth |

| Tape/Glue residue | No | No | Slight, sanded, smooth | Sanded, smooth |

Sanding: Smooth, only blending or inconspicuous streaks or chatter marks permitted

Other Characteristics Not Permitted: Boat or large symmetrical patches, open bark pockets, wet pitch, grease/oil or colored chalk, mechanical defects and press marks not allowed in face grades

Sea Corporation Lumber is a leading provider of high-quality Southern Yellow Pine, known for its durability, strength, and aesthetic appeal. With a strong heritage and extensive industry experience, we excel in delivering premium lumber for construction, flooring, and custom projects, both locally and internationally.

©2024. Sea Corporation inc. All Rights Reserved.